Can you move cards backwards on a Kanban board? This is one of the most common questions and concerns of people learning about Kanban. In the following article, I share a few thoughts on this question. This article will be relevant if you are:

- Service Delivery Manager, Service Request Manager using Kanban to manage the delivery of your service and improve the organisation

- Scrum Master, Product Owner, Scrum Team Member who are using Kanban within the Scrum framework

- Portfolio Manager or Program Manager, using Kanban to manage the flow of initiatives in your system

- Kanban Practitioner, Agile Coach exposed to the Kanban system implemented to support different services and product development initiatives

In the following paragraphs, I will elucidate what moving cards backwards means. Then, I will describe the Kanban Method and its relationship to the Toyota Production System. The next paragraph will clarify the concepts of Jidoka and Andon. Following that, I will list and describe the benefits of not moving cards backwards. Finally, I will present exceptions and conclusions. Enjoy reading!

What does moving cards backwards on a Kanban Board mean?

Moving a card backwards is common among less mature teams using Kanban. Moving cards backwards on a Kanban board refers to shifting a work item to an earlier stage in the workflow, typically when an issue, like a defect or incomplete task, is identified (Anderson, 2010). In one scenario, the team is moving a card backwards from one stage, ie, when the test fails. The work item is sent back to development to be fixed, and progress is made from that point. Alternatively, some of the team might decide that instead of moving the card backwards, a new work item will be created to address the issue, which starts at the beginning of the workflow.

Kanban Method and Toyota Production System

This article is dedicated to individuals and teams who use the Kanban Method. It is a method for defining, managing, and enhancing services that deliver knowledge work. (Kanban University, 2024). The insights for the Japanese automotive industry were one of the main sources of inspiration for the Kanban method.

The origins of the Kanban method are rooted in the Toyota Production System (TPS). In TPS, kanban is a visual scheduling tool that optimises workflow and inventory management on the production line. Developed by Toyota in the 1940s, inspired by supermarket restocking practices, Kanban (Japanese for “signboard”) uses visual indicators like cards, bins, or digital signals to signal when materials need replenishment or tasks require execution (Womack, 2007). Founded on a pull-based principle, it aligns production with actual demand, minimising waste and overproduction. Workers use kanban signals to trigger just-in-time delivery or production of parts, enhancing efficiency, reducing excess inventory, and supporting continuous improvement.

The same principles from the automotive industry were adopted to knowledge work and incorporated into the Kanban method. Explaining two more concepts from the Toyota Production System, Jidoka and Andon, will be helpful. I will briefly describe in the following paragraphs.

Jidoka

Often translated as “automation with a human touch,” is a core pillar of the Toyota Production System. It emphasises the empowerment of workers to stop production when a defect is detected, thereby ensuring quality at the source. Originating from Sakichi Toyoda’s early 20th-century loom innovations, which automatically halted when threads broke, Jidoka integrates human judgment with automated processes to prevent defective products from advancing (Womack, 2007). The four steps of Jidoka are illustrated in the diagram below

The four steps of Jidoka. Based on (Liker, 2004) Source: own elaboration

The first step involves detecting the abnormality. In this step, machines or operators identify any deviations from the standard (e.g., product defects, mechanical failures). The second step is to stop the process, either automatically or manually, to prevent the defect from progressing downstream. Andon, as a visual management tool, is used in this step. The third step focuses on fixing or containing the immediate problem. The key goal is to investigate and respond to the issue quickly, ensuring minimal disruption and no further defects. Finally, the last step is to identify and eliminate the root cause. In this step, root cause analysis is conducted (e.g., using 5 Whys), and the root cause should be addressed while implementing permanent countermeasures to prevent recurrence.

Andon

It is a visual management tool – often a light or signal board—that alerts workers and supervisors to issues on the production line, enabling a rapid response to problems flagged under Jidoka. A simplified version of the Andon system is presented in the diagram below.

The worker identifies an issue and stops the line (step 2 of Jidoka) using the Andon system. The system visually signals the specific location, fostering immediate problem-solving and continuous improvement. Jidoka and Andon offer significant benefits in quality assurance, waste reduction, and workforce empowerment. These principles are easy to incorporate into the Kanban Method (for delivering knowledge work). Use your imagination and consider how you might incorporate Jidoka and Andon into your Kanban system; it highlights the principles that can assist you in making decisions about moving cards backwards on the Kanban board.

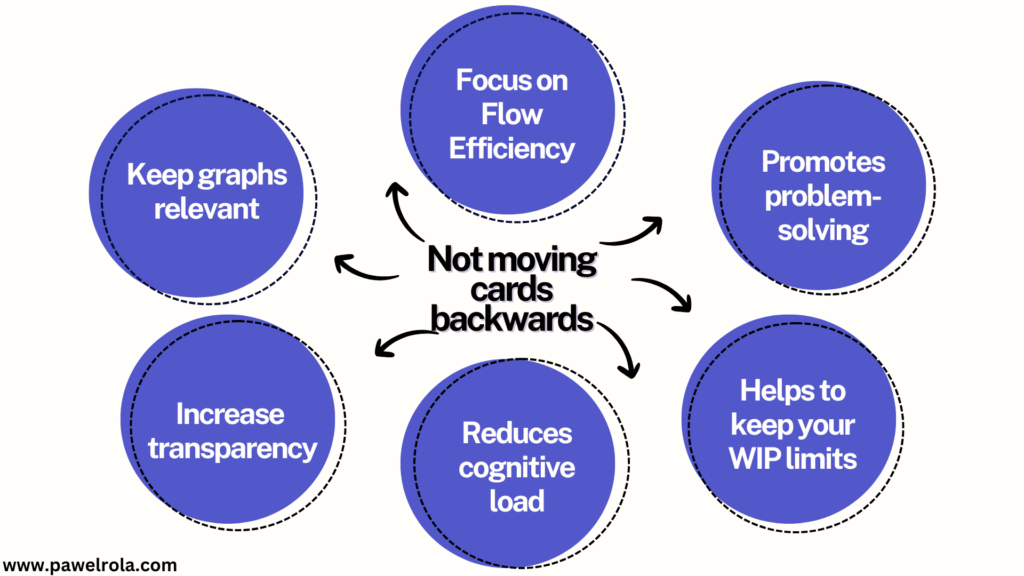

What are the benefits of not moving cards backwards on a Kanban Board?

Let us consider the benefits of not moving the card backwards in the Kanban system.

Focus on Flow Efficiency

Preventing cards from moving backwards ensures that work progresses in a linear, forward-moving direction, reducing disruptions and maintaining a smooth workflow. This minimises cycle time and prevents bottlenecks caused by revisiting earlier stages (Anderson, 2010)

Promotes problem-solving

Once issues are noticed, team members can address them immediately without further delay. In that case, cards on the Kanban board stay within the current workflow stage instead of moving a card back or creating a new card for rework. This encourages immediate problem-solving activities and prevents masking quality issues. It focuses team members on them, similar to the principles of Jidoka and Andon, and helps the team to focus on flow.

Helps maintain WIP limits

Moving the card backwards could result in a violation of the WIP limits policy. At the flow stage, it might exceed its full capacity. Not sending the card back prevents you from violating WIPs at the flow stage, which might exceed its full capacity.

Reduces cognitive load

Avoiding backwards movement reduces context switching. Once a problem occurs, people working on a specific work item do not send this work backwards and start a new job; instead, they swarm on the problem with other team members and try to find a solution.

Increases transparency

The stages in the Kanban system’s workflow should model knowledge discovery states. Each stage adds new knowledge or information to the work item. Moving backwards on pieces of knowledge work does not mean that you have undiscovered or unlearned something. In that sense, you reduce transparency about the current knowledge about a piece of work.

Keep graphs relevant

Your flow graph will be negatively impacted if the card is moved backwards. The usability of the CFD diagram (a diagram that tracks the flow of work through different stages) will not be significantly reduced. In most cases, moving work items back in the workflow will be immediately visible on the CFD and negatively impact reasoning and decision-making.

Long story short

Shall we move the cards back on the Kanban board?

NO (*).

*in most cases

Moving cards backwards on a Kanban board doesn’t make sense and does not bring any major benefits. Not moving work items backwards in the process has been proven to be a great strategy in the automotive industry, leading Toyota to be known as a quality leader. Jidoka and Andon are deeply embedded in Toyota’s philosophy and culture. I recommend learning from this experience for knowledge and teams using the Kanban method or implementing Kanban inside the Scrum framework.

You’ve probably begun to wonder why the answer has an asterisk, adding some ambiguity. Not moving cards backwards offers various advantages (listed above).

When to temporarily agree on moving cards backwards on a Kanban Board?

Every Kanban implementation needs to consider the crucial factor, people. In some situations, people need to learn from their own experience. Discovering and learning good practices based on experience might be the right path for your team. An Agile coach, Delivery Manager, or Scrum Master who supports the team in a Kanban implementation should remain pragmatic and results-oriented.

Introducing strict policies contradicting existing practices within a team may result in resistance to change. Coaching and guiding that meet customers where they are and allow them to learn from their mistakes will bring the best results. The role of the supporting individual is to ensure that learning takes place. Support the team in reflecting on their experiences, allowing them to inspect and adapt accordingly, with support from experienced personnel as needed.

If you need help with your Scrum and Kanban implementation or support in your digital, business, operation or Agile transformation, visit pawelrola.com or contact me on LinkedIn.

Let’s work together to bring the organisations of the future!

Share this content:

Bibliography

Womack, J. P. (2007). The Machine That Changed the World: The Story of Lean Production– Toyota’s Secret Weapon in the Global Car Wars That Is Now Revolutionizing World Industry. Free Presss.

Kanban University. (2024, 10 5). Kanban Glossary. From https://kanban.university/glossary/: https://kanban.university/glossary/

Anderson, D. J. (2010). Kanban: Successful Evolutionary Change for Your Technology Business: Successful Evolutionary Change for your Technology Business: Successful Evolutionary Change for your Technology Business. Blue Hole Press.

Kanban Univeristy . (2022). The Official Guide to The Kanban Method. https://kanban.university/.

Liker, J. K. (2004). The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. McGraw-Hill. .